Technology continued to sweep the world in 2015, and manufacturing practices evolved in tandem. Across the industry, working smarter was on the mind of everyone from the plant floor to the warehouse and front office. This was also prominently displayed at Rockwell’s Automation Fair, which focused on The Connected Enterprise–”a convergence of information technology (IT) and operational technology (OT) leading to a tighter integration between industrial assets and the rest of the enterprise value-chain”.

This conversation will only accelerate in 2016. Here are the three manufacturing trends to watch in the new year:

1. Lean Manufacturing: Do More With Less

Lean manufacturing developed as a discipline to eliminate waste, and has evolved to encompass the idea of maximizing all input resources. While this gains traction with some factors of production, the labor force is drastically changing as well. Factories are recruiting lower numbers of skilled laborers, which will make production and serving customer needs increasingly difficult moving forward. Fortunately, with the changing landscape and needs, technology is keeping pace. Machines can be monitored to report inefficiencies, radios can communicate both voice and data messages, and technology can multiply the efficacy of each skilled worker to compensate for a modified workforce.

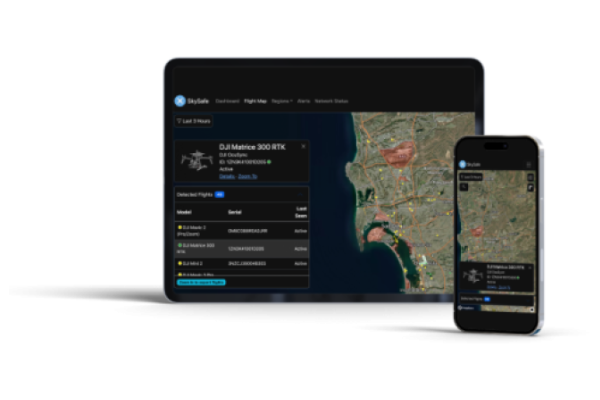

2. Industrial Internet of Things (IIoT): Productivity Through Connectivity

The Industrial Internet of Things (IIoT) is the environment where smart sensors connected to objects give those objects a ‘digital voice’ that allows them to autonomously connect and share data with one another – and the front office – over an IP connection. By 2020, an estimated 50 billion things will be connected in this way. This will enable machines to automate many of the processes that used to be slowed down by human interaction. As was discussed at Rockwell Automation Fair 2015, smarter machines can be be better controlled thereby increasing efficiency. These lead to faster time to market, lower total cost of ownership, improved asset utilization and better enterprise risk management.

3. Cybersecurity: Keep Data Safe

While an increased reliance on technology has incredible benefits for organizations, there is also a dark side to connectivity. By automating processes, many companies put themselves at risk of cyber attacks if they do not put the proper safeguards in place. Nearly nine out of every ten companies were breached in the past year, and critical manufacturing was in the top sixteen targeted sectors. Threats can come from anywhere, ranging from disgruntled insiders and criminals, to industry competitors, or simply careless employees. However, there are clear processes, like patching known vulnerabilities, and vigilant monitoring, that can significantly reduce the likelihood of a data breach.

Technology is bringing manufacturing to new levels of efficiency and enabling it to adapt to the increasingly connected world. Throughout 2016 and beyond, manufacturers around the globe will follow these trends as they look to work smarter than ever before.